Aerospace Machining Services

Precision-Crafted Components for Mission-Critical Performance

Our Approach

Universal Machining & Engineering LTD delivers high-tolerance aerospace machining solutions built to meet the industry’s strict requirements for accuracy, reliability, and safety.

Overview

High-Precision Aerospace Machining You Can Depend On

With over 50 years of machining excellence, Universal Machining & Engineering LTD provides aerospace manufacturers with complex, tight-tolerance components engineered for flawless performance.

Our team specializes in machining parts that must withstand extreme temperatures, vibration, pressure, and demanding operational environments. Whether for commercial aircraft, defense systems, satellites, or unmanned aerial vehicles (UAVs), we deliver parts you can trust in the air and beyond.

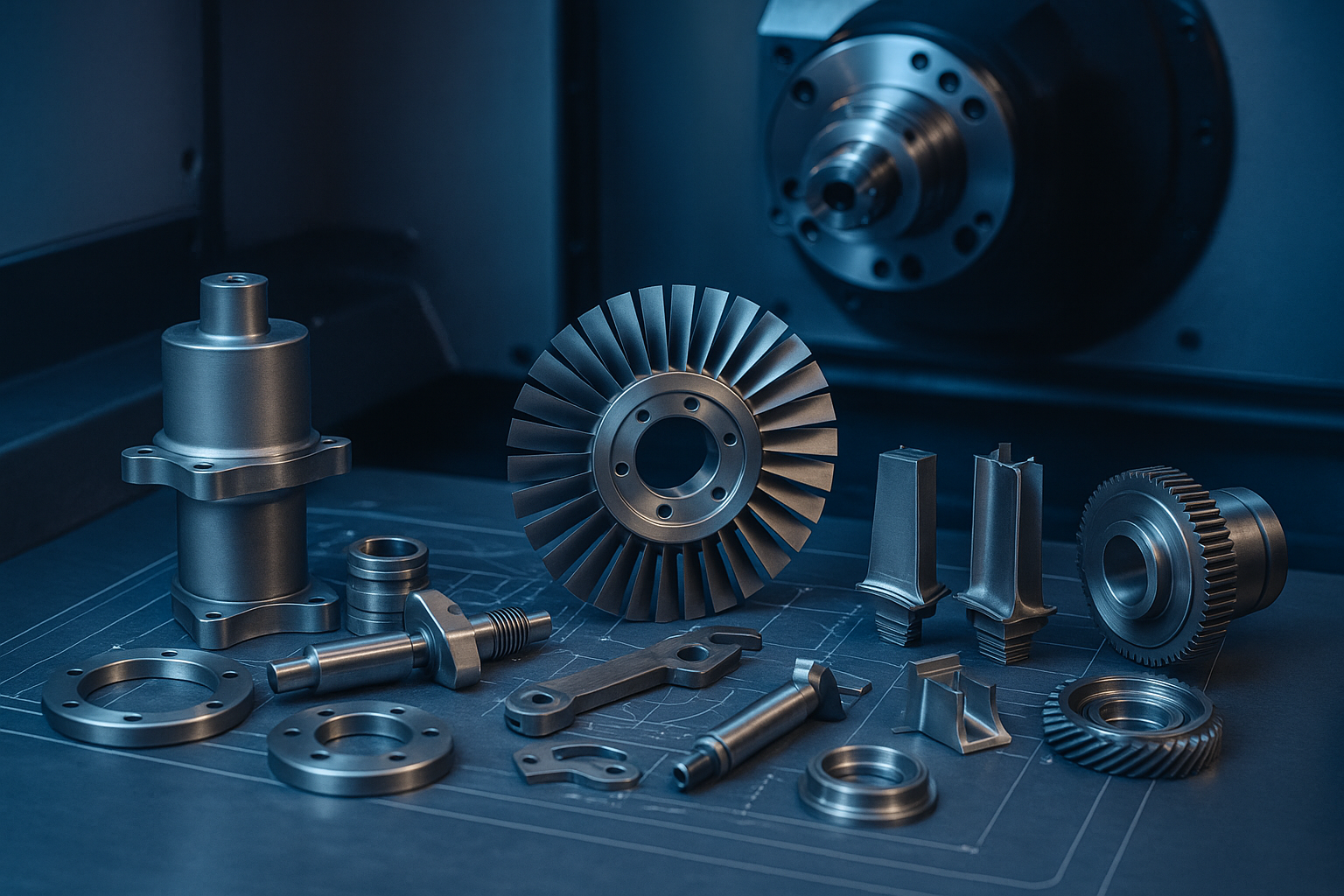

Our Aerospace Machining Capabilities

Advanced CNC Solutions for the

Aerospace Industry

We manufacture a wide range of precision aerospace components, including:

Turbine and engine parts

Housings, brackets, and structural components

Actuator components

Shafting and gear components

Fastening and connector systems

High-tolerance rings, bushings, and sleeves

Custom prototypes and production parts

Our capabilities include:

CNC Milling

Multi-axis milling for complex geometries and precision finishes.

CNC Turning

High-accuracy turning for cylindrical aerospace parts.

Surface Finishing

Polishing, deburring, edge finishing, and coating prep.

Prototyping & R&D Support

Fast turnaround for design validation and performance testing.

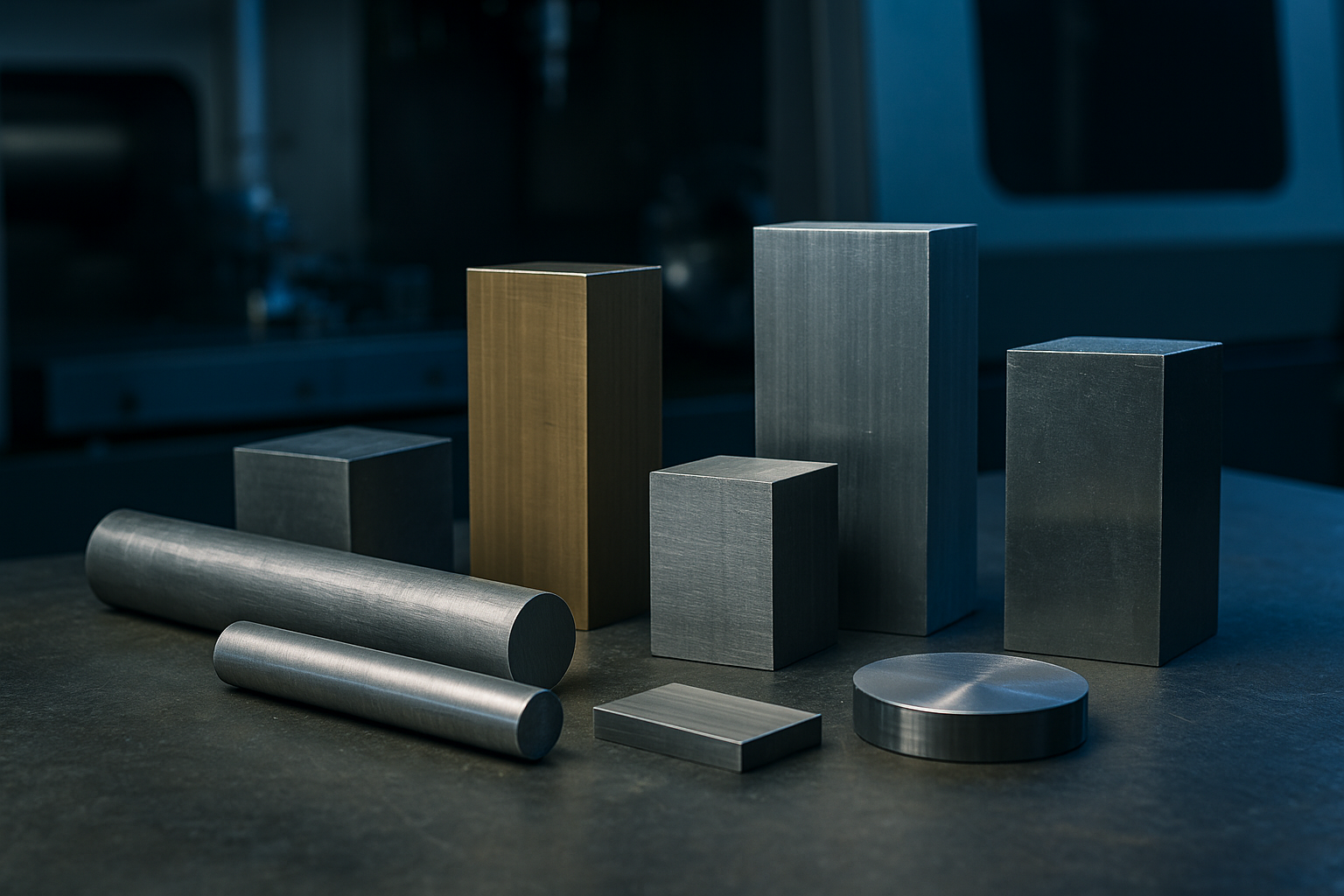

Materials We Machine

Aerospace-Grade Metals & Alloys

We work with high-performance aerospace materials, including:

Aluminum (6061, 7075, etc.)

Stainless steel (304, 316, 17-4)

Titanium

Inconel

Nickel alloys

High-strength steels

Engineering plastics (PEEK, Ultem, Delrin)

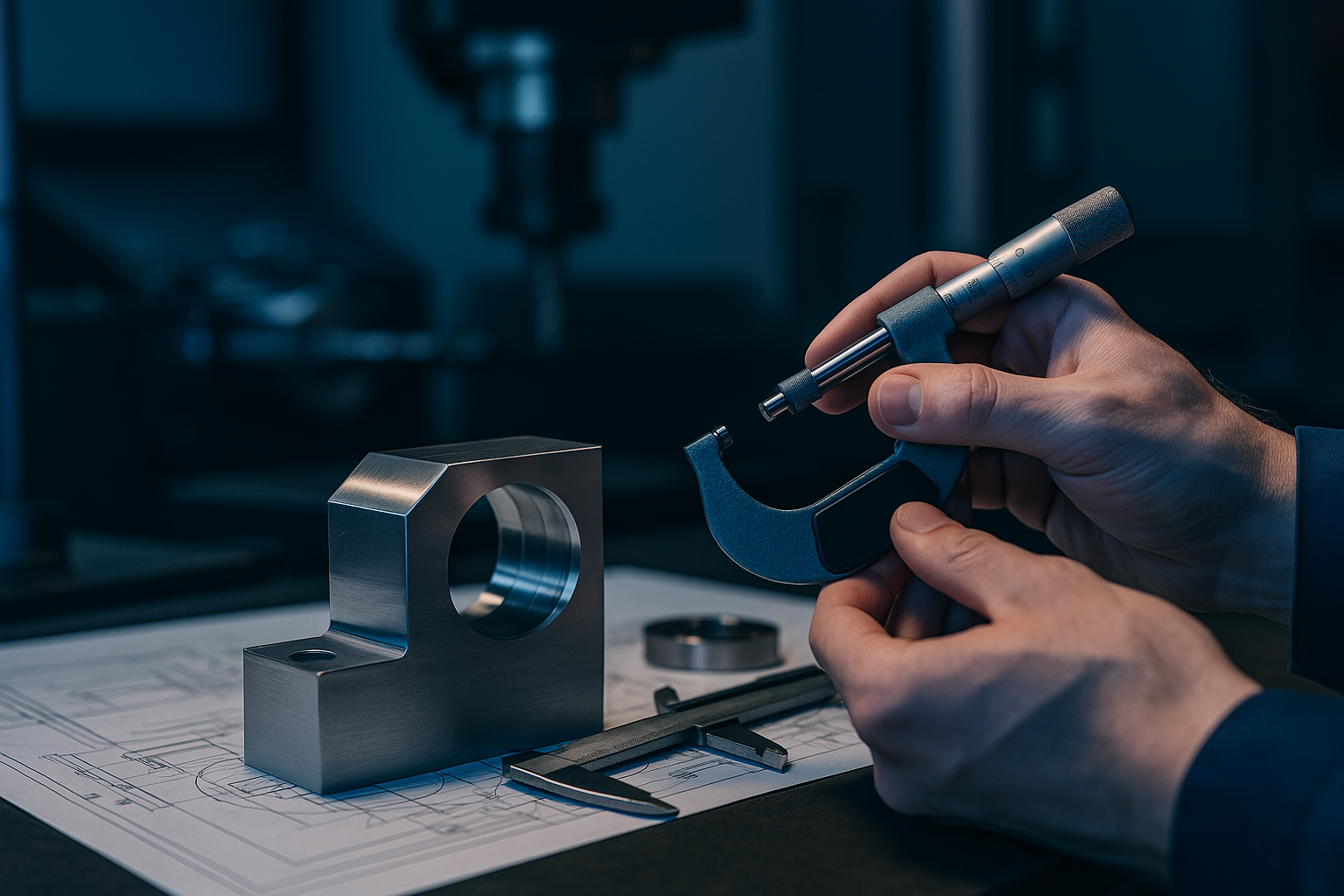

Quality & Compliance

Precision You Can Rely On

Aerospace components demand the highest level of accuracy.

We follow strict inspection procedures using:

Micrometers, calipers, and gauge tools

Digital measurement systems

CMM (Coordinate Measuring Machine) inspection

Full traceability and documentation

Every part is inspected to meet aerospace tolerances and safety standards.

Why Choose Us for Aerospace Machining?

50+ years of machining expertise

High-precision, tight-tolerance production

Experience with aerospace-grade materials

Fast prototyping and production scalability

Reliable quality control and consistent results

Collaborative engineering support

Applications

We Support

Our aerospace components are used in:

Commercial aircraft

Defense aviation

Helicopters

Satellite systems

Drones & UAVs

Spacecraft hardware

Engine assemblies

Flight control systems

Start Your Aerospace Project

Your Trusted Partner in Aerospace Manufacturing

At Universal Machining & Engineering LTD, we deliver components engineered for performance, strength, and reliability.

Whether you need prototype development or full production runs, our team is here to help.