A Complete Guide to CNC Surface Finishes and Coatings

Introduction

After a part is machined to the correct dimensions, the next crucial step is choosing the right surface finish. The finish you select affects appearance, corrosion resistance, durability, friction, and even how the part performs in real-world applications. From basic machining marks to mirror-polished surfaces and industrial coatings, the right finish can greatly enhance both function and longevity.

This guide breaks down the most common CNC surface finishes, how they’re applied, and how to choose the best one for your project.

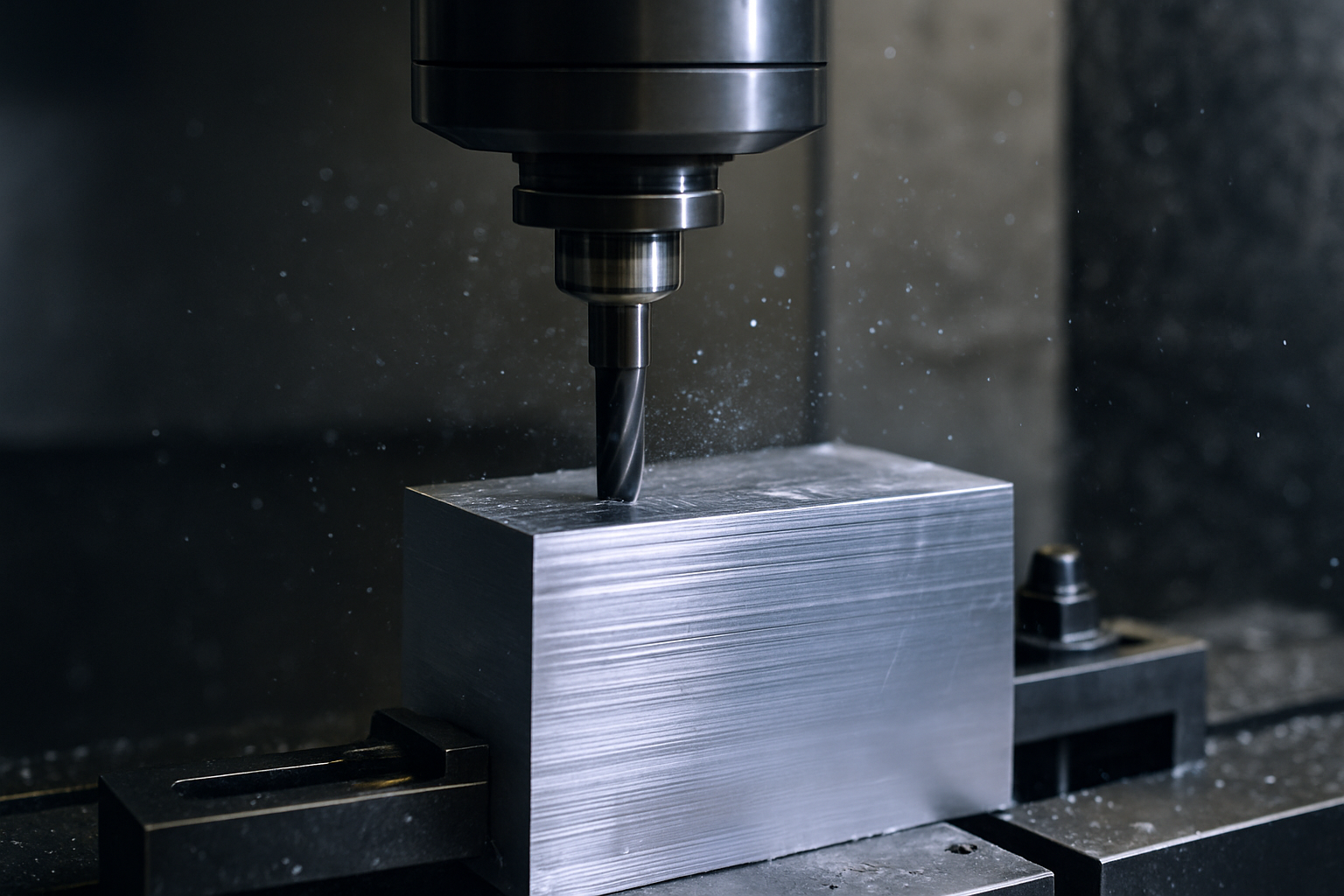

1. As-Machined Finish (Standard)

Appearance: Visible tool marks, matte sheen

Best for: Internal components, prototypes, non-cosmetic parts

The simplest and most economical finish. Parts come directly off the CNC machine with standard toolpath marks.

Benefits:

No additional cost

Fast turnaround

Good for functional parts that don’t need cosmetic appeal

2. Bead Blasting

Appearance: Smooth, matte, uniform texture

Best for: Consumer products, housings, visual prototypes

Bead blasting uses pressurized glass beads to remove tool marks and create a consistent satin finish.

Benefits:

Excellent for anodizing prep

Hides machining marks

Gives a premium, professional look

3. Anodizing (Type II & Type III Hardcoat)

Appearance: Colored or natural matte coating fused to surface

Best for: Aerospace, electronics, consumer products, wear-resistant parts

Type II (Standard Anodizing):

Decorative and corrosion-resistant

Available in colors (black, silver, red, blue, gold, etc.)

Type III (Hardcoat):

Much thicker, harder, and more durable

Ideal for high-wear environments

Benefits:

Corrosion and abrasion resistance

Increased surface hardness

Lightweight coating that doesn’t peel

4. Powder Coating

Appearance: Thick, colorful protective coating

Best for: Industrial equipment, brackets, enclosures

Powder coating creates a durable, uniform finish with excellent impact resistance.

Benefits:

Wide color range

Very durable

Great for steel and aluminum parts

5. Polishing (Brushed or Mirror)

Appearance: Smooth brushed texture or reflective mirror finish

Best for: Decorative components, consumer products, medical devices

Polishing removes imperfections and tool marks for a visually refined surface.

Types:

Brushed: Linear grain texture

Mirror: Highly reflective, near-perfect smoothness

6. Plating (Nickel, Chrome, Zinc)

Appearance: Metallic layer added to part surface

Best for: High-wear components, corrosion-prone environments

Common types:

Electroless Nickel: Uniform hardness, chemical resistance

Chrome Plating: High hardness and wear resistance

Zinc Plating: Corrosion protection for steel

7. Black Oxide

Appearance: Smooth black matte finish

Best for: Steel components needing mild corrosion protection

Black oxide adds a thin, dark coating that enhances appearance and reduces light reflection.

8. Powdered or Painted Finishes

Appearance: Uniform color coating, matte or glossy

Best for: Larger components or branding-specific parts

Paint is less durable than powder coating but ideal when color customization is needed.

How to Choose the Right Finish

Consider:

Appearance requirements

Wear resistance

Corrosion exposure

Material type

Budget

Production timeline

Each finish can dramatically change performance and cost, so it's essential to choose one aligned with your application.

Work With Your Machinist Early

Surface finishes may affect tolerances, material choice, and machining strategy. At Universal Machining & Engineering, we help customers choose the perfect finish to enhance both performance and aesthetics.

Conclusion

Surface finishes do more than improve appearance—they protect, strengthen, and extend the lifespan of machined parts. Choosing the right finish ensures your part performs exactly as intended.

Need Help Selecting the Right Surface Finish?

Our team can recommend the best finish or coating for your part’s environment, function, and budget.